Charging Systems

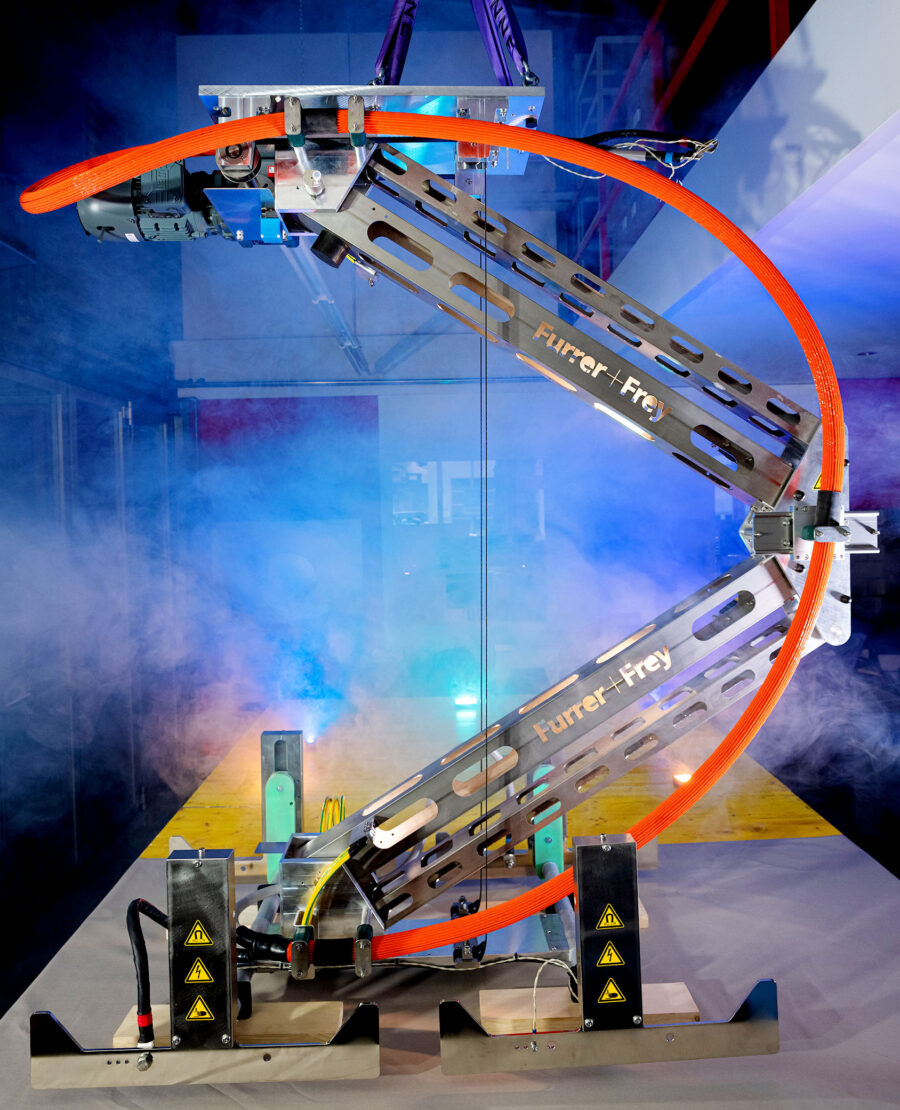

Pantograph

Electric charging stations play an important role in D/C connectivity solutions and KWenergy has made significant investments to improve a key component in the supporting hardware structure. Through innovation and a desire to maximise efficiency, our new pantographs are more durable, lighter and less expensive, benefiting both the customer and the end user.

What is The Pantograph?

The word pantograph is made up of the Greek words Panto / Panta meaning everything and Graph, meaning to write. Originally it was used to describe an early mechanical device for accurately copying and scaling drawings. Today, pantographs are used for railways and for vehicle charging stations, because they are similar in design and kinematics to the pantographs used in the past.

KWenergy’s pantograph is a device that is attached to a ceiling, e.g. of a bus depot. The arm lowers when the vehicle to be charged is positioned below and the charging process is started. The moving contacts signal the correct contacting, whereupon the actual charging process is electronically started and controlled. When the charging process is finished, the arm of the pantograph lifts the contacts away from the vehicle and returns to the rest position.

If autonomous vehicles are used, this system can also be used to fully automate the entire charging process.

Target customers are operators of vehicle fleets in the bus or truck sector. The current model is designed for use in bus depots. All components are also suitable for use in inclement weather conditions such as wind and rain / snow outside a depot.

Console:

The console is the interface to the higher-level charging infrastructure. It is used to attach the pantograph to the roof of the depot or to a frame. The drive motor and the attachment of the movable arm are attached to it.

Double Arm:

The double arm is used to lower the contact head vertically onto the vehicle. It transmits all forces between the contact head and the console and also serves to guide and hold the loading and signaling arms.

Contact Head:

All 4 movable contacts are attached to the contact head as an interface to the vehicle. 2 of the contacts are used for power transmission for charging, the other 2 are used for earthing and transmission of the signal for Control-Pilot.

Our pantograph has been developed with the following main points in mind:

- Simple construction

- Light weight

- Robustness

- Guaranteed constant contact force of 10 N per contact

- Secured contacting sequence (earthing, charging contacts, control pilot)

- Durability

- Low maintenance and easy replacement of parts

Our pantograph was subjected to extensive endurance testing during development, during which it completed over 300’000 cycles without interruption or damage.